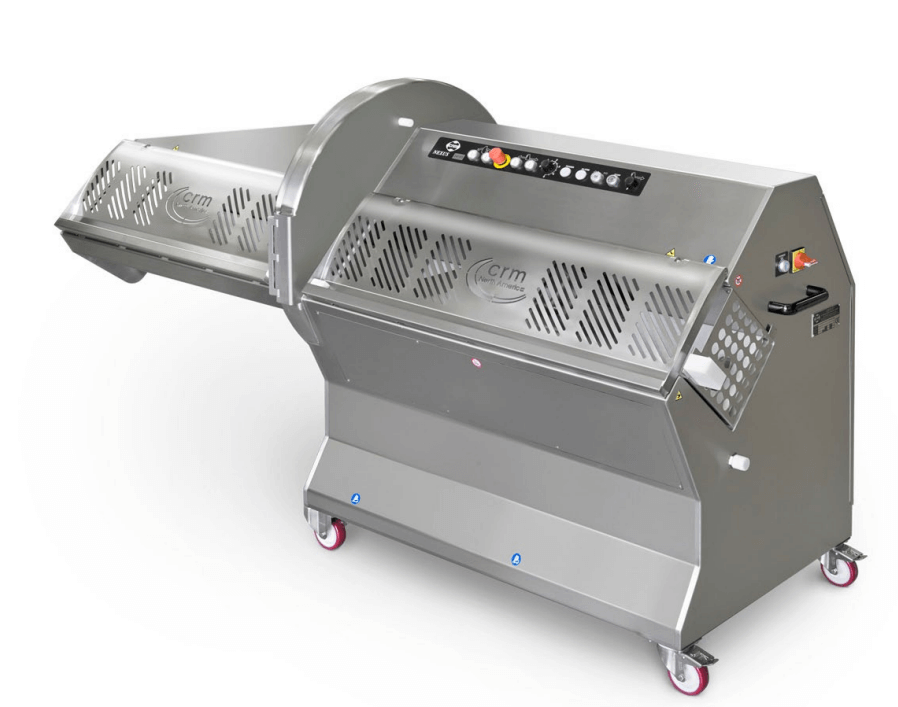

CRM Nexus 245-45-930

The NEXUS series automatic slicers cut fresh and frozen bone-in and boneless meat, cooked meat, smoked products, fish and cheese into parallel slices at high speed. The thickness of the slices can be set from 2 to 45 mm, even during slicing.

Thanks to the special geometry of the blade, the slice is cut with power and high precision, without splintering the bone and decreasing dramatically cutting waste. Made entirely of bacteriaproof AISI 304 stainless steel, the NEXUS slicers are fitted with systems making them safe and exceptionally easy to use, including by non specialist staff. Further, all machines can be opened without tools, and the food contact points easily inspected, making it a simple task for the operator to clean and ensure the total hygiene of the machine, preventing the formation of bacterial colonies, as demanded by “CE” European and American laws. Nexus machines ensure more regular slices, to the precise thickness desired, with higher yields and no bone splinters: meat are better presented and keep longer.

Above all NEXUS offers major labour and time savings, and cuts production costs substantially Optionals: A) CL electronic system to avoid waste (245ES); B) infeed conveyor belt to cut fresh meat without bones (245ES).

Specifications

STANDARD FEATURES

LABOUR SAVING

• Higher production in less time

• Machines can also be used by non-specialist staff

FEWER DISCARDS

• Up to 3% fewer discards than with other slicing systems

PRODUCT PRESENTATION

• Clean, parallel slicing

SAFETY

• Security system to european standards

HYGIENE

• Complete hygiene – to european standards

• Can be inspected without use of tools

TECHNOLOGY

• Electronic control system

215 Cuts/Min

POWER

5kW

WEIGHT

380kg

DIMENSIONS

240×260 mm

MAX PRODUCT LENGTH

930 mm

CRM Nexus 245-45-930

1268 Ga Highway 99

Townsend, GA 31331

Lakeland , FL 33801