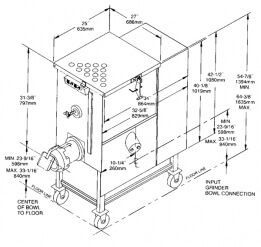

BIRO Model AFMG-52 Automatic Mixer Grinder

The Biro Model AFMG-52 (Auto-Feed Mixer-Grinder) is the ideal workhorse for large supermarket meat rooms and medium sized processors and HRI plants. Its 7.5 hp (5.6 kW) motor (or optional 10 hp, 7.5 kW motor) provides a production output of up to 100 lbs. (45.5 kg) per minute to give you the productivity you need.

The heavy duty roller chain auger drive system with tapered roller bearing journal box is separate from the heavy duty mixer motor interface gear drive system. This more efficient design transfers maximum torque power to the auger. The heavy duty stainless steel 200 lb. (91 kg) hopper and frame resist corrosion and damage, even in an environment of harsh cleaners. Your mixer grinder lasts longer and gives you more return on your investment. Power, durability, and low maintenance make the Biro Model AFMG-52 Auto-Feed Mixer- Grinder a meat room workhorse.

STANDARD PADDLE

OPTIONAL 1ST GRIND PADDLE

Model AFMG-52

Optional (EC) accessory cleaning/ drying/storage rack (A57203), cart not included

Specifications

MODEL

AFMG-52 Auto-Feed Mixer-Grinder

CONSTRUCTION

Heavy duty stainless steel hopper, lid, paddle, frame and legs. Cast iron hot tin dipped Size 52 bowl, ring and auger.

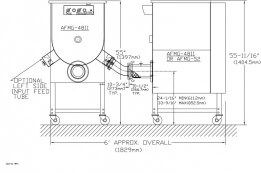

AFMG-52 to AFMG-52 Tandem System

SWITCH

WATERTIGHT MAGNETIC WITH THERMAL OVERLOAD AND UNDER VOLTAGE PROTECTION.

POWER CORD

12’ #10 GA – 4 STRAND CORD WITH PLUG 7.5 HP, U.S., 12’ #10 GA – 4 STRAND CORD NO PLUG 7.5 HP INTERNATIONAL, 12’ #8 GA – 4 STRAND CORD WITH PLUG 10HP U.S., 12’ #8 GA – 4 STRAND CORD NO PLUG 10HP INTERNATIONAL.

HOPPER CAPACITY

HOPPER: 200 LBS. (91 KG). A 400 LB. (182 KG) IS ALSO AVAILABLE, SEE AFMG-52-4.

GRINDING CAPACITY

OUTPUT – UP TO 100 LBS (45.5 KG) PER MINUTE.

DRIVE SYSTEM

AUGER: SINGLE REDUCTION (35 PITCH – 4 ROW) ROLLER CHAIN DRIVE WITH TAPERED ROLLER BEARINGS. SEE OPTION EC (POLY) BELT AUGER DRIVE SYSTEM. MIXER: HEAVY DUTY MOTOR INTERFACE GEAR DRIVE SYSTEM.

SAFETY

MAGNETIC SAFETY INTERLOCK ON HOPPER LID.

STANDARD FEATURES

STAINLESS STEEL 2ND GRIND PADDLE WITH CENTER ARMS, 5” DIA. TOTAL LOCK SWIVEL CASTERS WITH ANTI-MICROBIAL WHEELS, SPURT GUARD, EXTRA ROD FOR FRONT, LEFT OR RIGHT SIDE OPENING LID, POWER CORD (SEE ABOVE), RING WRENCH, BOWL NUT WRENCH, TWO SHEAR PINS WITH SCREWS, RECEPTACLE FOR ELECTRIC FOOTSWITCH, OPERATING AND SAFETY MANUAL.

OPTIONS (EC)

SIZE 52 PLATE AND KNIFE, SINGLE-REDUCTION “EAGLE” SELF-CENTERING, NO STRETCH, NO LUBRICATION, POLY BELT AUGER DRIVE, ELECTRICAL OR PNEUMATIC FOOTSWITCH, ACCESSORY CLEANING AND STORAGE RACK, EXTRA LONG STAINLESS STEEL LEGS (33”/838mm TO 42”/1069mm) FROM FLOOR TO BOWL CENTER, SIZE 52 LEFT HAND 35 DEGREE SIDE INLET, CONNECTIONS FOR TANDEM OPERATIONS, 10 HP (7.5 KW) AUGER MOTOR, STAINLESS STEEL BOWL, RING, AND AUGER (ENTERPRISE OR UNGER STYLE).

OPTIONS (NC)

SIZE 52 RIGHT HAND 35° HOPPER FEED INLET (SEE DRAWING).

CERTIFICATION

U.S.D.A., U.L., N.S.F., C.S.A.

WEIGHT

UNCRATED: 759 LBS. (343 KG) APPROXIMATE. CARTON PACKED: 863 (391 KG) APPROXIMATE. WOOD CRATED: 962 LBS. (436 KG) APPROXIMATE.

DIMENSIONS CRATED

L=50” (1270 MM), W=36” (914.4 MM), H=66” (1676 MM)

Item Number LIT AFMG-52-231

Motors

| MOTOR | HP | KW | TYPE | VOLTS | AMPS | CYCLE | PH | CODE |

|---|---|---|---|---|---|---|---|---|

| AUGER | 7.5 | 5.6 | TEFC | 208-230/460 | 24-21/11 | 60 | 3 | STD |

| MIXER | 1.75 | 1.3 | TEFC | 208-230/460 | 5.7-5.2/2.6 | 60 | 3 | STD |

| AUGER | 10 | 7.5 | TEFC | 208-230/460 | 31-28/14 | 60 | 3 | EC |

| AUGER | 7.5 | 5.6 | TEFC | 575 | 8.8 | 60 | 3 | EC |

| MIXER | 1.75 | 1.3 | TEFC | 575 | 2.4 | 60 | 3 | EC |

| AUGER | 10 | 7.5 | TEFC | 575 | 11 | 60 | 3 | EC |

| AUGER | 7.5 | 5.6 | TEFC | 220/380-415 | 22/12.7-11.6 | 50 | 3 | STD |

| MIXER | 1.75 | 1.3 | TEFC | 220/380-415 | 5.9/3.4-3.1 | 50 | 3 | STD |

| AUGER | 10 | 7.5 | TEFC | 220/380-415 | 28/16.2-14 | 50 | 3 | EC |

TEFC= TOTALLY ENCLOSED FAN COOLED STD=STANDARD EC=EXTRA COST NC=NO CHARGE

For Pricing & To Schedule Installation, Call Now.

Townsend, GA

Headquarters

Stalmic Distributors Inc

1268 Ga Highway 99

Townsend, GA 31331

Lakeland, FL

Warehouse

Lawrenceville, GA

Warehouse

Stalmic Distributors Inc. primarily operates in the Processing and Packaging Equipment business / industry within the Wholesale Trade - Durable Goods sector.